- Home Page

- Company Profile

-

Our Products

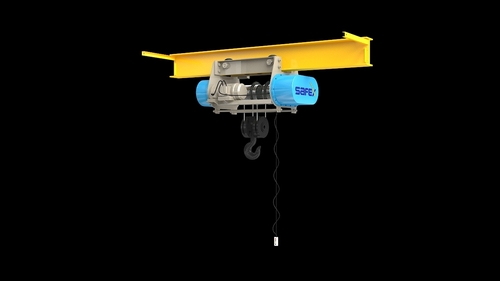

- Rope Hoists

- Goods Cum Passenger Lifts

- Flame Proof Elevators

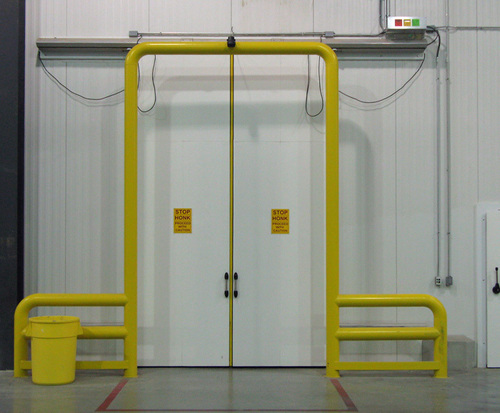

- Goods Lift

- Industrial EOT Cranes

- Industrial Lifts and Elevators

- MRL Elevator (Gearless High Speed)

- Goods Cum Passenger Elevator

- Goods Elevators

- Jib Cranes

- Chain Hoists

- Industrial Hoist

- Autodoor Lift

- Semi Goliath Cranes

- Heavy Duty Gantry Crane

- Underslung EOT Crane

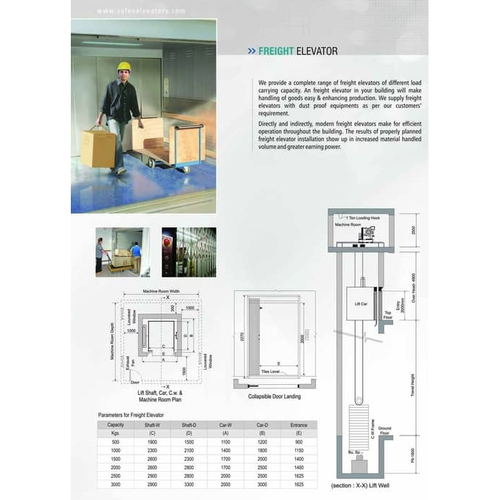

- Freight Elevator

- RMG Crane (Rail Mounted Gantry Crane)

- HOT Cranes

- Bungalow Elevator

- Car Elevator

- Double Girder EOT Crane

- More Info

- Contact Us

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese